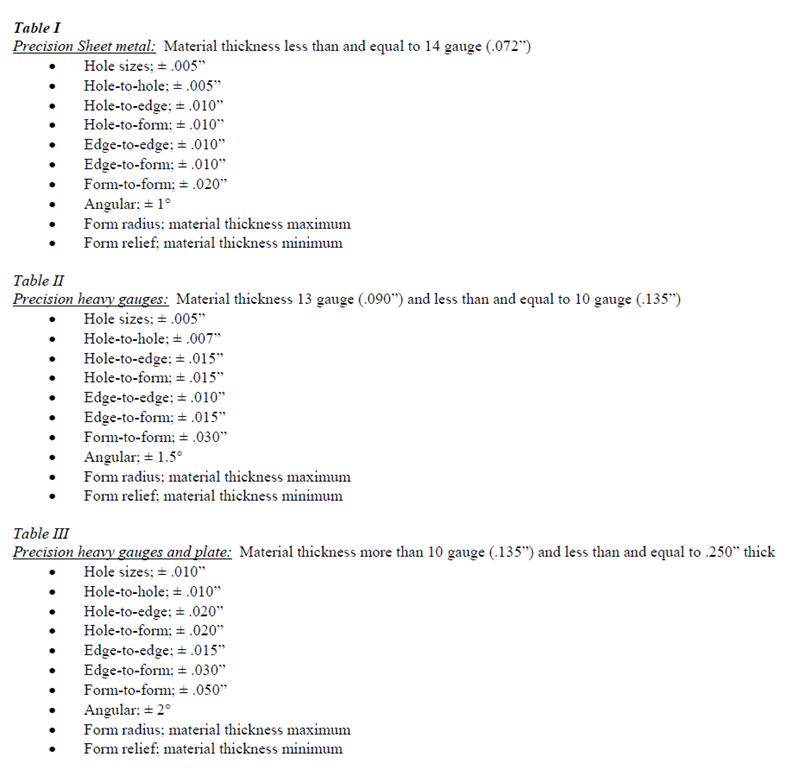

Tolerance Standards

Scope:

The procedures outlined in this document apply to the preferred manufacturing methods adopted by Dynamic Design & Manufacturing, Inc.

These procedures may affect any and all work centers and are subject to overall part size and material type. The word "part" refers to the three-dimensional aspects and features of a manufactured detail).

The procedures outlined in this document are to be used for parts that fit all of the following criteria:

- A drawing or part file that is missing tolerances.

- Our standard tolerances can be safely substituted for tolerances stated on drawing or part file in order to add value to the customer by lowering manufacturing costs.

- The size of the part is too large to measure using precision instruments.

- The parts' material type, size, and/or thickness is such that closer tolerances may be more difficult to consistently hold, and therefore more costly to manufacture.

Purpose:

- The procedures are intended to aid in establishing conformance to the capability of the processes listed above.

- They are intended to streamline the qualification process at these work centers while at the same time provide a more thorough review of the variables. They should provide for a higher success rate in both quality and profitability.

Procedures:

Drawings and part files will be reviewed on a case-by-case basis at the time of a bid. Statements regarding tolerances will be posted in hard copy on the bid response sent to the customer.

The following tables are subject to change where necessary.

Click to submit a Request a Quote or call us at 303-652-0431